APPLICATIONS

Wet drum separators are used in magnetic media recovery, purification of solids carried in liquid suspension and in iron ore concentration. Heavy media plants require a wet drum magnetic separator that meets the following criteria:

- Magnetic separators can be found in most mineral processing operations, especially those processing non-metallic minerals and magnetic ores. This article investigates the use of high intensity magnetic separators and magnetic separation equipment in the minerals sector with a focus on processing dry materials (in the -15mm, +45 micron size range).

- ASGCO ® ’s Magnetic Separator overhead magnet is a non-electric suspended separator, suspended over a conveyor or head pulley to remove ferrous metals.

- Electromagnets Electromagnetic Separators use wire coils and direct current to provide a magnetic field which can be used to separate ferrous material from non ferrous products. Electromagnetic separators offer greater flexibility and strength as well as different magnetic fields for specific applications.

A plate separator is a magnetic plate mounted inside a chute. The magnetic field’s strength is concentrated away from the magnet surface. As material slides down the chute, the magnetic field reaches out into the flowing material. This attracts ferrous contaminants to. Permanent Magnetic Separators are designed to separate ferrous materials from non-ferrous substances has a wide range of application. Our extensive range of equipment meets growing industry demands.

1. Magnetic separators which recover magnetics contained in feed slurries as efficiently as possible, to reduce the per ton/media consumption of treated product to a minimum.

2. Recovery of magnetic solids in as clean a magnetic concentration as possible, to keep the separating bath at a low viscosity and eliminate misplaced product.

3. A high gravity magnetic discharge to eliminate, in many cases, the need for a densifier. A high gravity concentrate simplifies the plant operation.

4. Trouble free operation with minimum down time, minimum operator attention and minimum maintenance cost.

TYPES OF WET DRUM MAGNETIC SEPARATORS

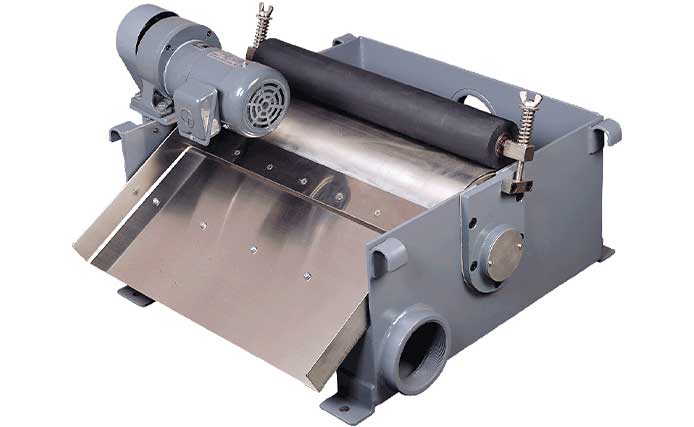

Advent dt2410 driver download for windows 10. Con-Current Single Drum Wet Magnetic Separator. This is probably the most commonly used type of wet drum magnetic separator used in heavy media plants today. Adaptec raid 52445 driver download for windows 10. Tank arrangement is illustrated above. It gives the maximum cleaning of magnetic solids, recirculation of material passing through the wash spray back to the feed, and the highest magnetic solids discharge of the types discussed herein.

Counter-Current Single Drum Wet Magnetic Separator. This configuration is illustrated above. The advantages of this type of separator are maximum magnetic recovery, can tolerate heavy mag- netic loads, is less susceptible to loss of magnetic efficiency at high feed volumes (up to 80 GPM/Ft.), and the magnetic discharge is on the feed side of the separator.

Double Drum Separators will increase the volumetric capacity of the wet drum magnetic separator.

Our Wet Drum Magnetic Separators are available in the following drum diameters: 15″, 30″ and 36″.

Standard drum lengths are: 15″, 24″, 36″, 48″, 60″, 72″, 84″, 96″, 108″ and 120″.

| Catalog Number | Description | Feed/Discharge (@20% Solids Feed) |

|---|---|---|

| 060B-010 | 15″ X 9″ Length | 25 GPM/1 TPH |

| 060B-012 | 30″ X 24″ Length | 150 GPM/8 TPH |

| 060B-013 | 30″ X 36″ Length | 220 GPM/12 TPH |

| 060B-014 | 30″ X 15″ Length | 75 GPM/4 TPM |

Factors Influencing Separator Selection

Five basic factors influence proper selection of a magnetic separator in terms of drum diameter, magnetic width, and type of wet drum separator for use in a specific application. Acer 8935g driver download for windows. These are:

1. Volume of rinse slurry to be handled.

2. Percent of solids in rinse slurry.

3. Percent of magnetics in the feed solids of the rinse slurry.

4. Required magnetic recovery efficiency.

5. Cleanliness required in the magnetic concentrate product.

One of the features of our magnetic separators is its ability to handle widely fluctuating loads. Therefore applications can be fount lying outside the service limits indicated. However, the limits outlined below are basic guide lines which will assure efficient magnetic separator performance. These guide lines will indicate changes that can be made in existing plants to improve media recovery efficiency. Each factor is considered separately, but all factors must be considered jointly for each particular application.

Magnetic Separator Belt

Feed Volume

Feed volume should not exceed 75 GPM/Ft. of magnet width on a 30 inch diameter single drum separator. If feed volumes up to 90 GPM/Ft. must be handled, a double drum separator (rougher, scavenger model), in which the primary drum tailings and overflow product are sent to the secondary drum, should be applied. Efficient magnetic recovery cannot be expected at rates beyond 90 GPM/Ft.

Percent Solids In Feed

Magnetic Separator Drums Youtube

The ratio of magnetic to non-magnetic solids cannot be effectively insulated from total percent solids in evaluating magnetic recovery. As a general rule, the limiting recommended feed solids in a media circuit is 50 percent. Variations of the ratio of magnetic to non-magnetic solids within this solids range can produce many potential feed slurries. The recommended maximum percent solids for a single drum separator is 15% for con-current separators, 20% solids maximum can be tolerated without losing magnetic efficiency. Beyond 20% solids, double drum separators (rougher, scavenger) are recommended.

In cases where the feed slurry goes above 30% solids, which sometimes occurs when a cyclone is being used to thicken a dilute rinse slurry product, sufficient water should be added in the feed box of the primary separator to bring the solids concentration down to 30% solids. For the discharge rate of a 36″ diameter separator, add 20% to the above volume.

Percent Of Magnetics In The Feed Solids Of The Rinse Slurry

The ratio of magnetic to non-magnetic solids will influence the purity of the concentrate obtained. The non-magnetic content tends to deter effective magnetic cleaning when the non-magnetic to magnet ratio exceeds 40% by weight. If the feed pulp is sufficiently dilute (below 20% solids), purity of magnetic concentrate will not be seriously affected at the 40% concentration. When the total solids exceed 20% and when the non-magnetic solids exceeds 40%, it is difficult to obtain a high purity concentrate. This lopsided condition usually occurs in plants using reclaimed water and is alleviated by pulp dilution; or by running the media through the magnetic separator while the plant is not running, thus further rejecting non-magnetics.

Magnetic Separator Coal

A primary limitation in magnetic separator selection influenced by percent solids and percent magnetics in the solids, is the magnetic discharge loading on the magnetic separator. Single drum 30 inch diameter concurrent separators should be limited to 3 TPH of magnetic discharge per foot of magnet width. These magnetic recovery discharge limits are suggested in line with good magnetic recovery efficiencies. Counter-current separators can retain magnetic recovery at a sacrifice in magnetic cleaning at a discharge rate 30 percent higher than the above figures.

A double drum magnetic separator will permit the magnetic discharge to increase to as much as 30% above the indicated single drum rate. Optimum magnetic cleaning and recovery can be obtained with a double drum separator with con-current primary drum separator and with counter-current secondary drum separator.

SEPOR, INC 718 N FRIES AVE. WILMINGTON, CA 90744 | 310 830 6601 | Fax: 310 830 9336 | info@sepor.com